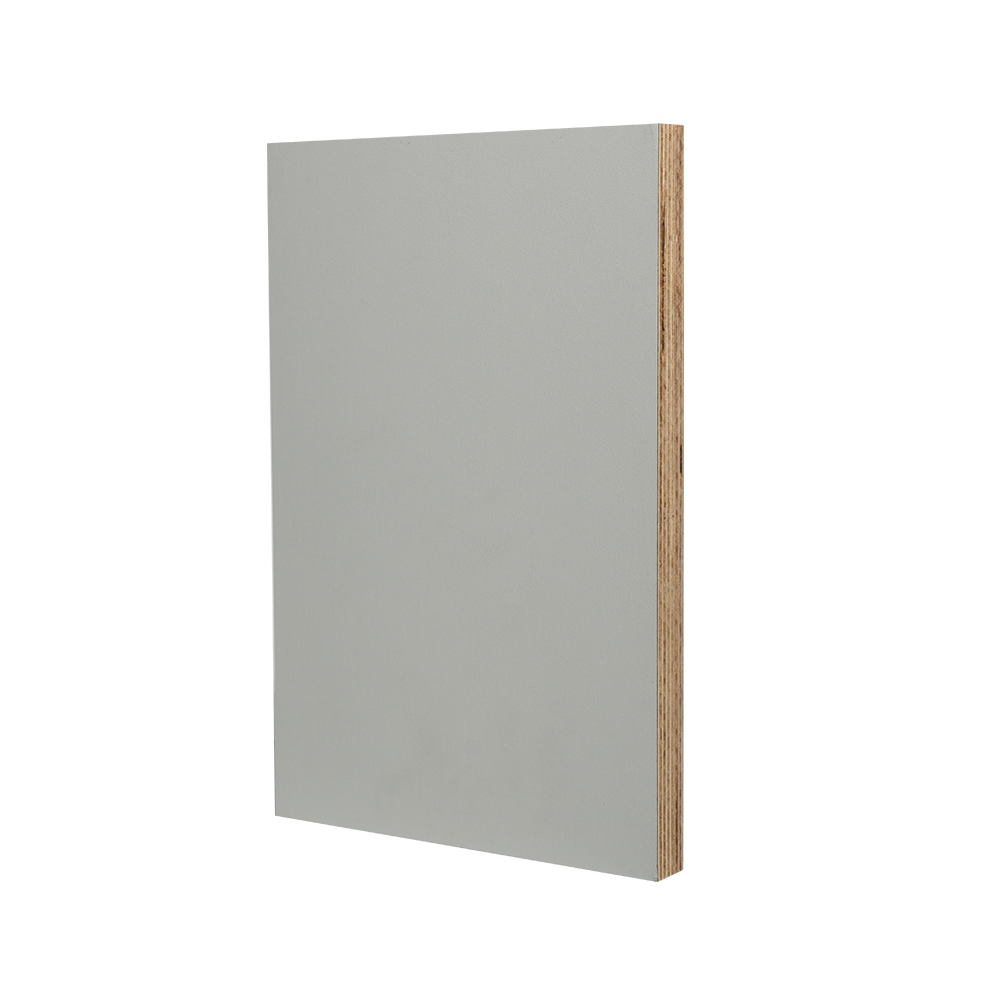

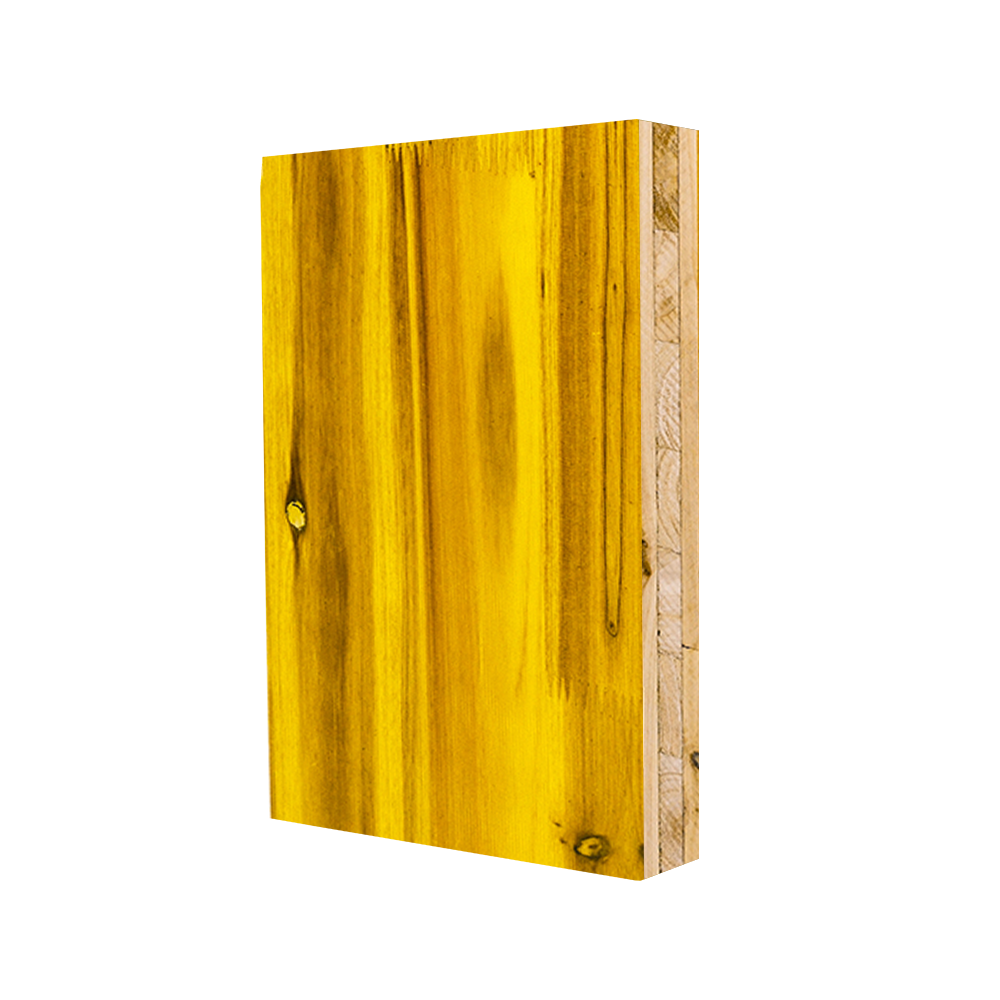

Material structure of HPL Birch Plywood

In the field of modern architecture and furniture manufacturing, the choice of materials not only affects the appearance of the product, but is also directly related to its performance and service life. As a new type of composite material, HPL (High Pressure Laminated) Birch Plywood has gradually become a popular choice in the industry with its excellent material structure and wide application.

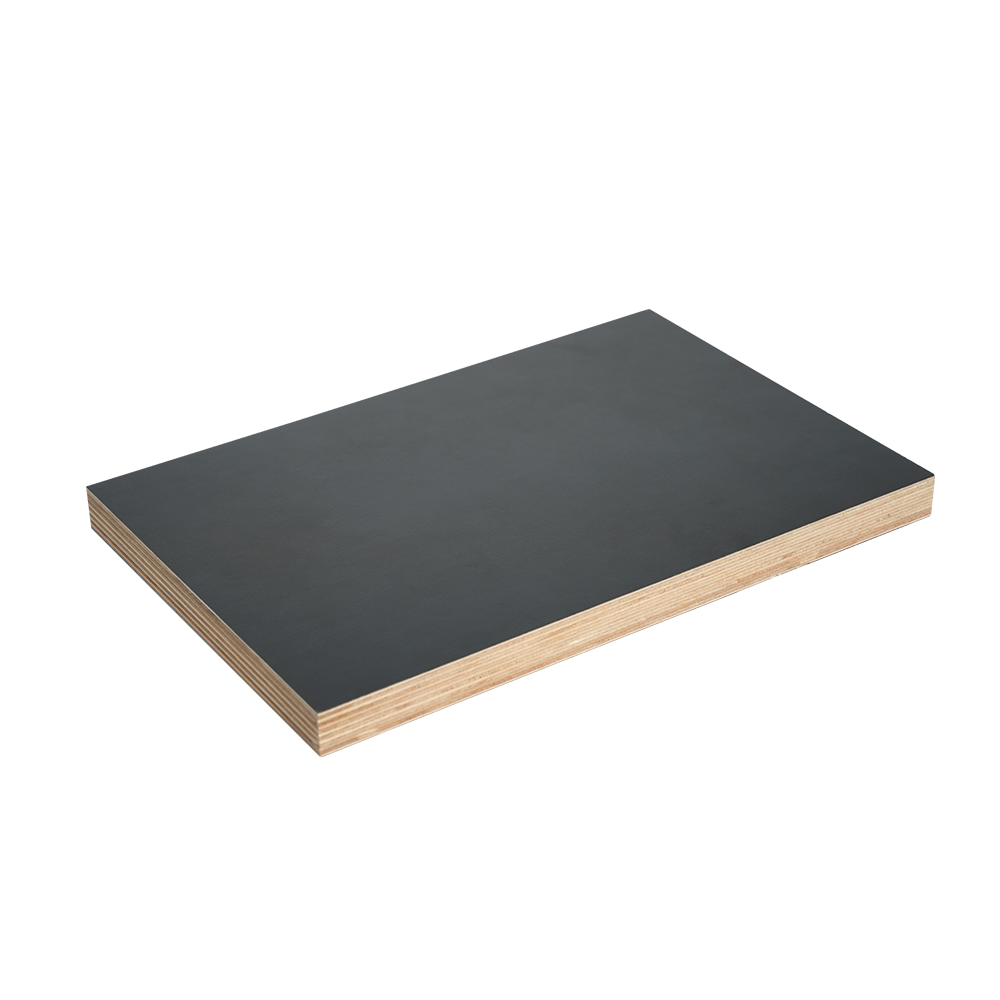

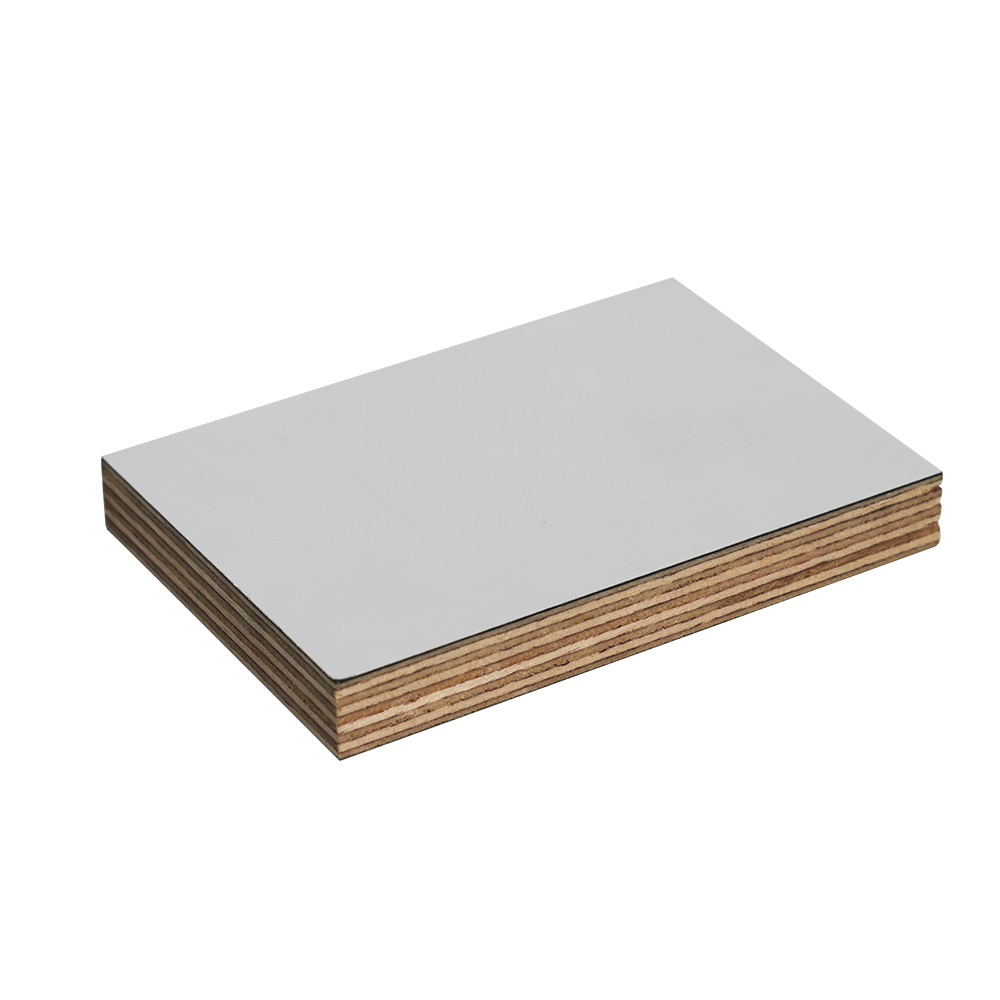

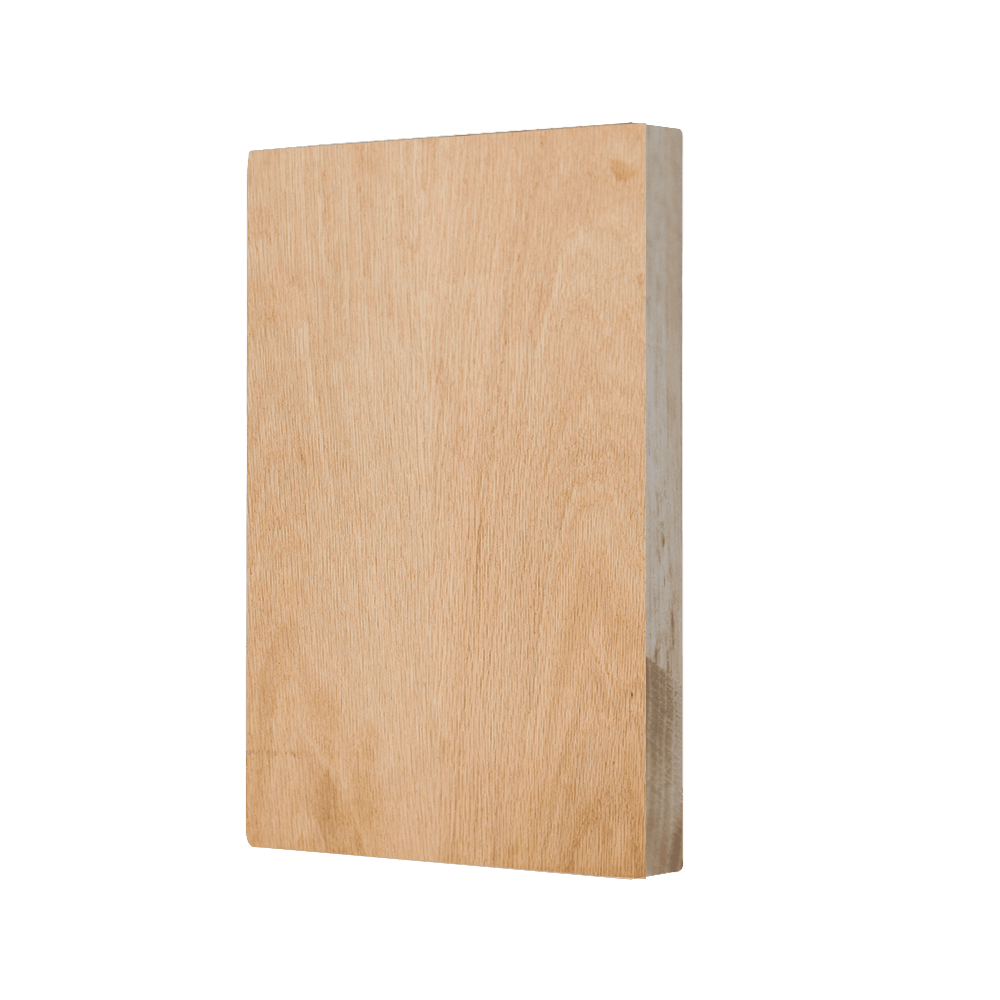

Core material: pure birch plywood

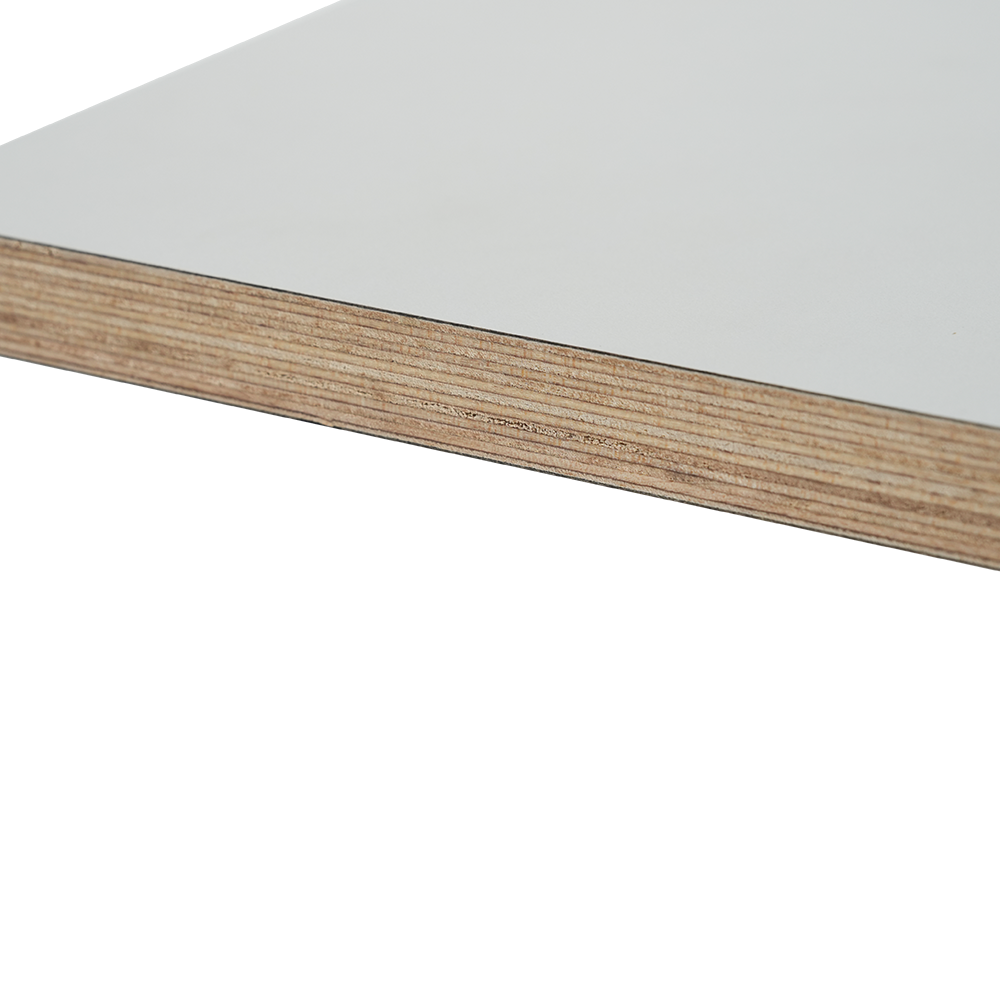

The core material of HPL birch plywood is pure birch plywood, which is made of multiple layers of birch veneers stacked in an interlaced manner. This design not only improves the strength and stability of the material, but also effectively reduces the risk of deformation and cracking of wood under different environmental conditions. As a high-quality wood, birch has good mechanical properties and corrosion resistance, making it an ideal choice for manufacturing high-quality plywood.

Laminar structure

HPL birch plywood adopts a multi-layer interlaced laminated structure, and the fiber directions of each layer of birch veneer are perpendicular to each other. This design can effectively disperse the pressure and stress applied by the outside, and improve the overall resistance to bending and tearing. The laminated structure enables HPL birch plywood to maintain good shape stability when bearing heavy loads, avoiding deformation caused by external factors.

By stacking birch veneers in an alternating pattern, HPL birch plywood resists the natural shrinkage and expansion of wood. This design ensures that the plywood remains stable under different humidity and temperature conditions, significantly extending its service life.

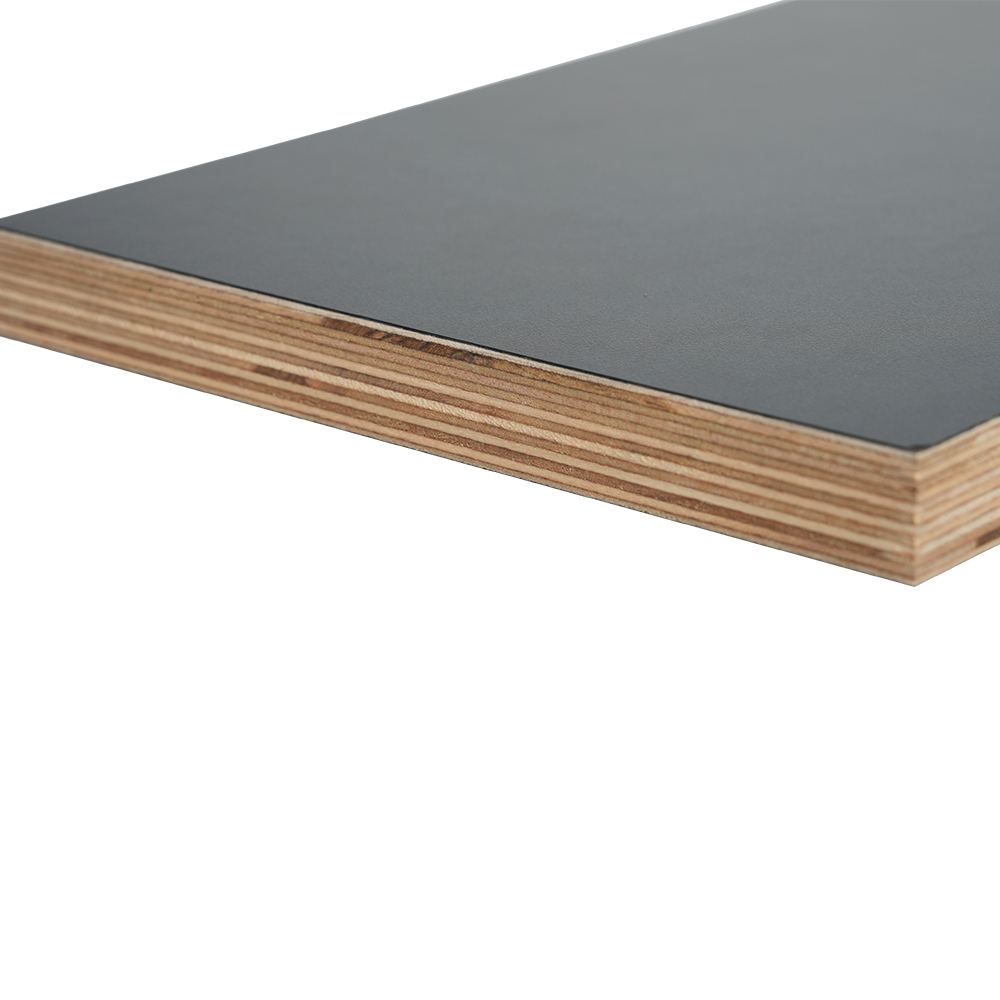

High-pressure lamination process

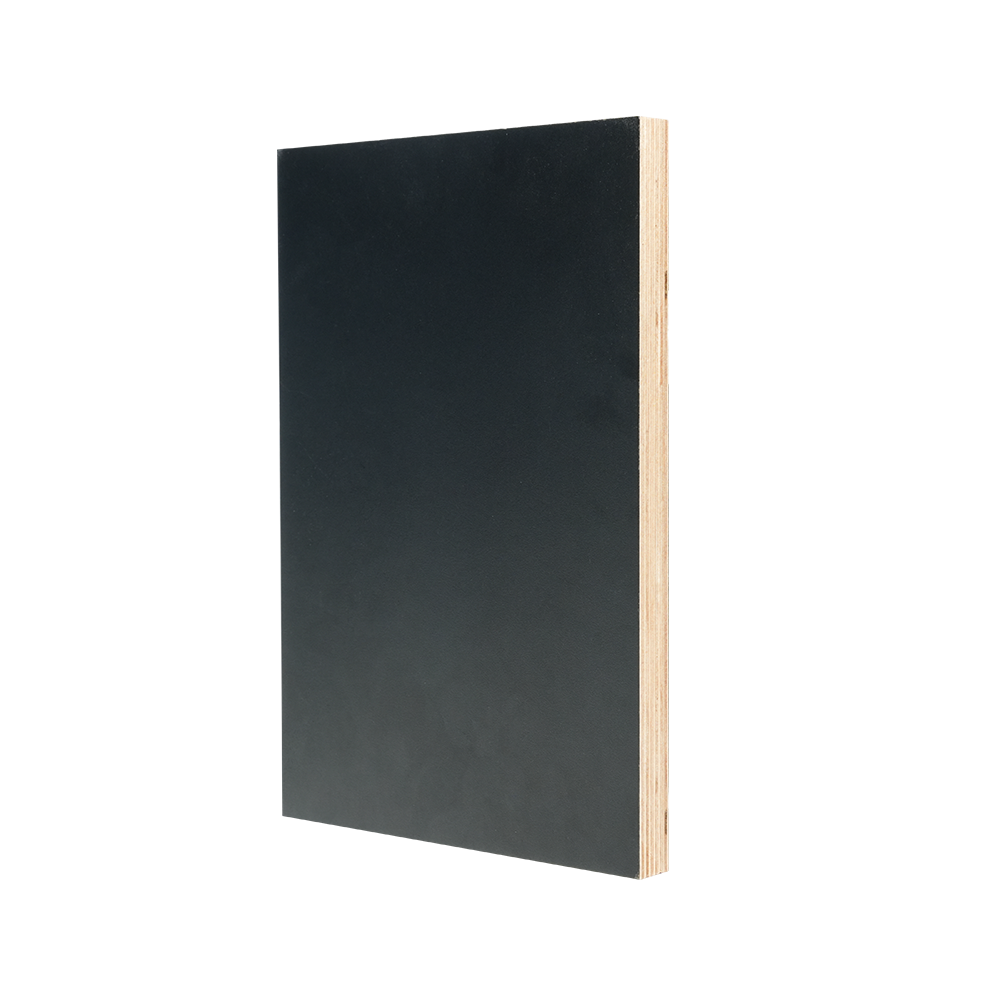

A notable feature of HPL birch plywood is its high-pressure lamination process. This process forms a strong composite material by bonding the surface layer to the plywood substrate under high temperature and pressure. This process brings multiple advantages:

Abrasion resistance: The high-pressure lamination process forms a wear-resistant protective layer on the surface of HPL birch plywood, which significantly improves its resistance to scratches and abrasion. This feature allows HPL birch plywood to withstand various external impacts and wear in daily use, making it particularly suitable for furniture and decoration that is used frequently.

Corrosion resistance: The bonding of the surface layers during the high-pressure lamination process gives HPL birch plywood good corrosion resistance. Whether in a humid kitchen or bathroom environment, HPL birch plywood can effectively resist the erosion of moisture and chemicals, maintaining its structural and appearance integrity.

Aesthetics: High-pressure lamination not only improves the performance of the material, but also gives it a unique visual effect. HPL birch plywood can be customized in a variety of colors and textures according to customer needs to meet the needs of interior design in different styles.

Surface treatment technology of HPL birch plywood

The surface treatment technology of HPL (high-pressure lamination) birch plywood is a key process designed to improve the overall performance and aesthetics of the product. Through fine surface treatment, HPL birch plywood shows a smooth surface texture and delicate touch, giving users a high-quality use experience. This surface treatment not only improves the visual effect, but also performs well in functionality, making it stand out in many application scenarios.

Surface smoothness

The professionally treated HPL birch plywood has a smooth and flawless surface, which significantly reduces the adhesion of dirt and dust. This design concept is particularly important in high-frequency use environments such as kitchens and restaurants, which can effectively ensure the hygiene and beauty of the space. The smooth surface makes daily cleaning more convenient, and users can restore the surface finish with a simple wipe, which greatly improves the efficiency of use.

Stain resistance and durability

The surface treatment technology of HPL birch plywood gives it excellent stain resistance, which can effectively resist the invasion of oil stains, dirt and water stains. This feature ensures the clean state of the product during long-term use and reduces the maintenance cost caused by the accumulation of stains. Through advanced material selection and treatment technology, HPL birch plywood has excellent durability and is suitable for various commercial and home environments to meet high standards of use.

Wide application

Due to its unique surface treatment technology, HPL birch plywood is widely used in furniture manufacturing, interior decoration and commercial space design. In the office environment, HPL birch plywood can not only be used as a desktop material, but also as a partition, wall decoration, etc., to increase the beauty and functionality of the space. In the catering industry, with its excellent stain resistance and easy-to-clean properties, HPL birch plywood has become an ideal choice for dining tables and bars, and can withstand high-intensity use requirements.

English

English 中文简体

中文简体